A ship sacrificial anode is a critical corrosion-control component that protects vessels from long-term structural damage caused by electrochemical reactions in water.

This guide explains how sacrificial anodes work, where they are installed on ships, how materials are selected, what affects their lifespan, and why routine inspection and replacement are essential for safe and efficient vessel operation.

What Sacrificial Anodes Do on Ships

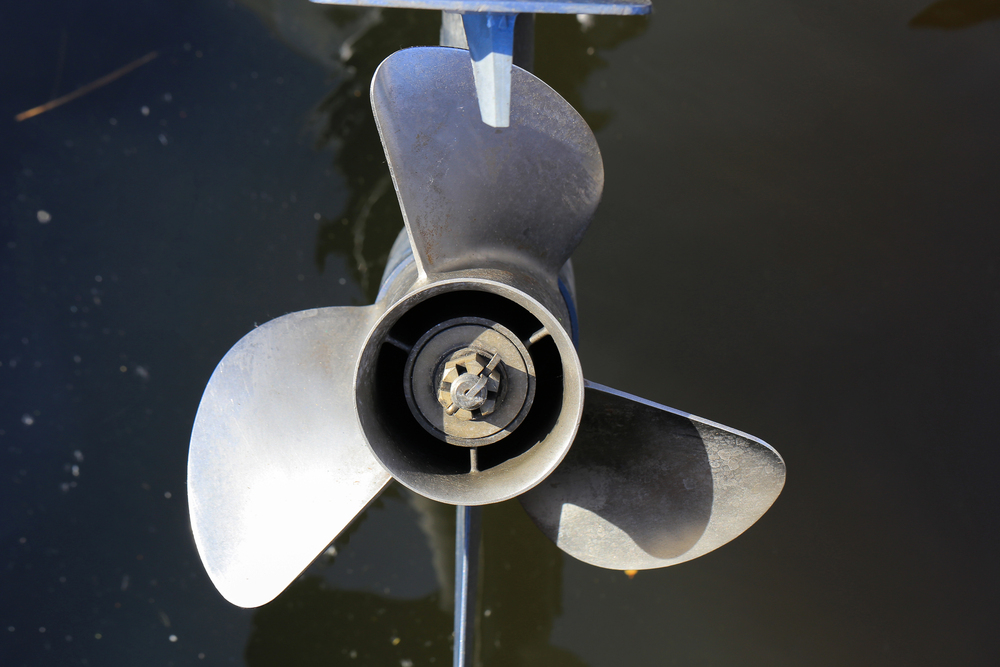

Sacrificial anodes protect submerged metal parts by corroding in place of more valuable components such as hull plating, propellers, rudders, shafts, and thrusters. This process is known as cathodic protection.

When dissimilar metals are submerged in water, electrical currents naturally form, leading to corrosion. An anode sacrificial system redirects this corrosion toward the anode, preserving the integrity of the ship’s structure.

On both commercial vessels and recreational boats, sacrificial anodes act as a controlled point of failure. Instead of allowing corrosion to spread unpredictably, the anode absorbs the damage and is replaced as part of routine maintenance.

Common Locations of Sacrificial Anodes on Ships

Sacrificial anodes are strategically installed on all areas of a ship where metal remains continuously submerged and exposed to corrosive conditions. These locations typically include the hull plating, propeller shafts, rudders, trim tabs, stabilizers, sea chests, thrusters, and other underwater fittings.

Each of these components is vulnerable because it is either made of dissimilar metals or experiences constant water flow, both of which accelerate electrochemical corrosion. In a properly designed ship sacrificial anode system, anodes are positioned close to the components they protect to ensure corrosion is drawn away efficiently.

Hull-mounted anodes are commonly spaced along the vessel’s sides and bottom to provide broad, uniform protection across large metal surfaces. Shaft and propeller anodes are installed directly on rotating components to counteract the increased electrical activity generated during operation.

Sea chests and intake grates often receive dedicated anodes because restricted water flow and debris buildup can intensify localized corrosion. Rudders and stabilizers also require individual protection due to their constant movement and exposure to turbulent water.

On a ship sacrificial anode system, placement is carefully planned to ensure even protection across the vessel. Improper placement can leave certain areas vulnerable, even if the anodes themselves are in good condition. This is why distribution and electrical bonding are just as important as anode size.

Types of Sacrificial Anode Materials

The most common anode materials used on ships are zinc, aluminum, and magnesium. Each material performs best in specific water conditions.

Zinc is widely used in saltwater environments due to its stable and predictable corrosion rate. Aluminum offers longer service life and performs well in both saltwater and brackish conditions. Magnesium is highly active and best suited for freshwater applications.

Choosing the correct anode sacrificial material is essential, as the wrong choice can either underperform or corrode too aggressively.

How Sacrificial Anodes Prevent Hull and Component Damage

Sacrificial anodes work by becoming the most electrically active metal in the system. This causes corrosive currents to flow toward the anode instead of the ship’s hull or propulsion components. Over time, the anode gradually erodes, signaling that it is doing its job.

On large vessels, multiple anodes are often installed to ensure balanced protection. A well-designed ship sacrificial anode layout prevents localized corrosion, pitting, and metal fatigue that can compromise safety and efficiency.

Factors that Affect Anode Lifespan

Several factors influence how long sacrificial anodes last on ships. Water salinity plays a major role, with saltwater causing faster consumption than freshwater. Electrical activity from onboard systems or nearby vessels can accelerate wear. Vessel usage, speed, and docking conditions also affect corrosion rates.

Because of these variables, there is no universal replacement schedule. Instead, routine inspection helps determine when sacrificial anode replacement is needed before protection is lost.

When Sacrificial Anode Replacement Is Required

Sacrificial anodes should typically be replaced once they have lost about 50 percent of their original mass. Beyond this point, their ability to protect surrounding metals drops significantly. Delaying sacrificial anode replacement exposes the hull and underwater fittings to direct corrosion.

Uneven wear, excessive pitting, or complete depletion are clear indicators that replacement should occur immediately. Regular inspections during hull cleaning or dry dock periods help catch these issues early.

Importance of Proper Installation and Bonding

Even high-quality anodes fail if installed incorrectly. Anodes must maintain clean, direct contact with the metal they are protecting. Paint, marine growth, or corrosion between the anode and hull can prevent electrical flow.

Proper bonding ensures that all protected components share the same electrical potential. Without correct bonding, corrosion may bypass the anode entirely, rendering the anode sacrificial system ineffective.

Sacrificial Anodes for Different Vessel Types

Commercial ships, workboats, and recreational vessels all rely on sacrificial anodes, though their systems vary in scale. Larger ships often use hull-mounted anodes combined with shaft and rudder anodes. Smaller vessels may rely on fewer units but still require careful placement.

For boats operating in marinas or near shore power connections, electrical interference can increase corrosion risk. In these cases, selecting and maintaining boat sacrificial anodes becomes especially important to prevent accelerated wear.

Inspection and Maintenance Best Practices

Routine inspection is the foundation of effective corrosion control. Sacrificial anodes should be checked at least every six months or during scheduled underwater maintenance. Divers assess wear patterns, attachment security, and bonding effectiveness.

Consistent monitoring allows vessel operators to plan sacrificial anode replacement rather than reacting to unexpected corrosion damage. This proactive approach reduces downtime and long-term repair costs.

Common Mistakes to Avoid

One common mistake is mixing different anode materials in the same vessel. This can disrupt electrical balance and reduce protection. Another issue is replacing anodes without addressing the underlying electrical problems, which leads to rapid depletion.

Failing to inspect anodes regularly often results in unnoticed corrosion spreading to critical components. Avoiding these mistakes ensures the ship sacrificial anode system performs as intended.

Long-Term Benefits of Proper Anode Management

Well-maintained sacrificial anodes extend the life of hulls, propulsion systems, and underwater fittings. They improve vessel reliability, reduce repair expenses, and support safe operations. Over time, consistent anode care proves far more cost-effective than repairing corrosion damage after it occurs.

Protecting Ships Through Reliable Sacrificial Anode Systems

Sacrificial anodes provide a controlled and proven method of preventing corrosion across ship hulls and underwater components. Regular inspection and timely replacement are key to maintaining continuous protection.

At Hull 2 Prop, we focus on providing optimal marine care through professional underwater maintenance and repairs across Florida. We support our clients with dedicated dive teams offering hull cleaning, anode replacement, and propeller repair to keep vessels protected and operating efficiently.

Schedule an inspection with our team today and protect your vessel before corrosion becomes costly.