Zinc anode replacement is one of the most important maintenance tasks for protecting boats from corrosion and expensive underwater damage.

This guide explains when zinc anodes should be replaced, how to identify wear, what factors affect replacement timing, and why following proven guidelines helps extend the life of your vessel’s critical components.

What Zinc Anodes Do and Why Replacement Matters

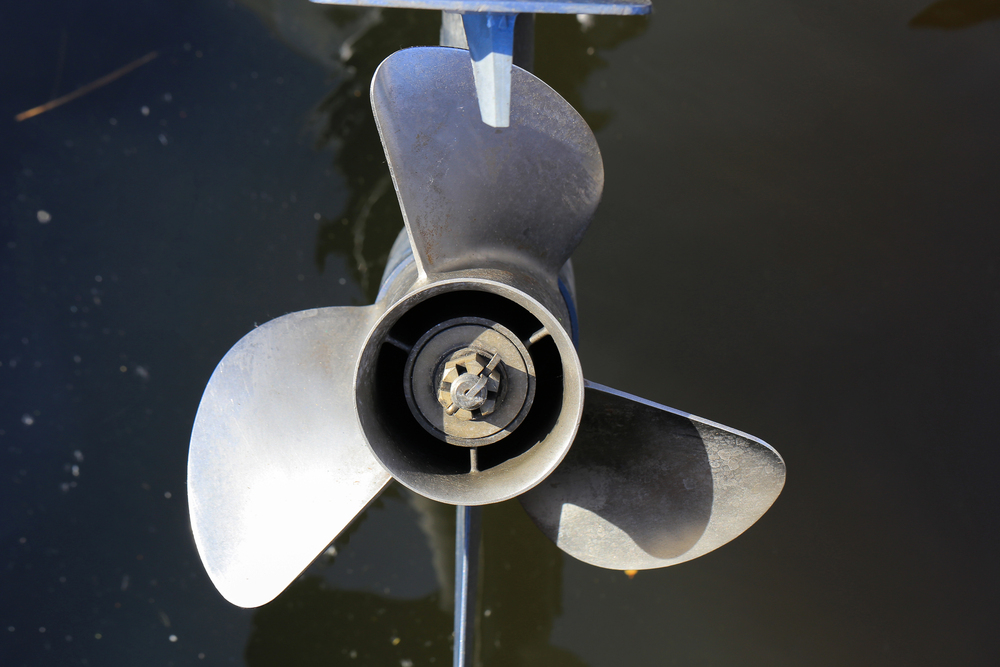

Zinc anodes are designed to corrode instead of valuable metal parts such as propellers, shafts, trim tabs, and thru-hull fittings. This process, known as cathodic protection, diverts corrosive electrical activity away from the vessel.

Over time, zinc anodes are consumed as intended, which is why routine zinc anode replacement is essential. When anodes are left in place too long, corrosion can spread quickly to exposed metal surfaces.

How Often Zinc Anodes Should Be Replaced

There is no universal timeline for anode replacement, but most zinc anodes last between six months and one year. Boats that remain in saltwater year-round or operate near marinas with heavy electrical activity often require more frequent inspections.

Following basic zinc replacement guidelines, anodes should be replaced once they have lost about 50 percent of their original mass. Waiting longer reduces their ability to provide effective protection.

Signs Your Zinc Anodes Need Replacement

Visual inspection is the most reliable way to determine when replacement is necessary. Anodes that appear heavily pitted, cracked, or unevenly worn are no longer functioning properly. If the anode looks smooth and coated, it may not be electrically active. Inconsistent wear patterns can also indicate stray current issues or poor bonding.

These signs should never be ignored, as delayed zinc anode replacement increases the risk of corrosion damage to underwater components.

Factors that Affect Replacement Frequency

Several environmental and operational factors influence how quickly zinc anodes are consumed. Saltwater is more conductive than freshwater, causing zinc to corrode faster. Boats docked near other vessels or connected to shore power may experience increased electrical interference.

Vessel usage also matters, as frequently operated boats generate more electrical activity. Understanding these conditions helps owners choose the right replacement for zinc and set realistic inspection schedules.

Proper Placement and Sizing Considerations

Replacing zinc anodes is not just about swapping old parts for new ones. Proper sizing and placement are critical for effective protection. Anodes must be installed close to the components they protect and maintain good electrical contact with the metal surface.

Using multiple smaller anodes rather than one large unit often provides more even protection. Correctly installed boat sacrificial anodes ensure corrosion is distributed evenly across protected areas.

Zinc Anodes Vs. Other Replacement Options

Zinc remains a common choice for saltwater environments, but it is not always the best option in every condition. In brackish or freshwater, zinc may form an oxide layer that reduces effectiveness. In these cases, aluminum or magnesium anodes may be considered as a replacement for zinc.

However, switching materials without professional assessment can create new corrosion risks. Vessel owners should evaluate water conditions before changing anode types.

Inspection and Maintenance Best Practices

Regular inspection is key to extending the life of underwater components. Most marine professionals recommend inspecting zinc anodes during scheduled hull cleanings or at least twice a year.

Inspections allow divers to check for wear, confirm secure attachment, and identify early signs of corrosion. Consistent monitoring supports timely zinc anode replacement and prevents unexpected failures.

Common Replacement Mistakes to Avoid

One common mistake is replacing anodes without cleaning the contact surface. Paint, marine growth, or corrosion between the anode and metal reduces electrical conductivity.

Another mistake is mixing anode materials in the same vessel, which can disrupt the protection balance. Following established zinc replacement guidelines helps avoid these issues and ensures reliable performance.

Why Professional Replacement Adds Value

While some anodes are accessible above the waterline, many critical anodes require underwater access. Professional divers can assess wear patterns, identify electrical issues, and confirm proper installation. This approach ensures zinc anode replacement is done correctly and provides full protection for the hull and propulsion system.

Keep Your Boat Protected Through Proper Zinc Anode Care

Replacing zinc anodes at the right time prevents corrosion from reaching expensive underwater components and supports long-term vessel performance. Consistent inspections and proper installation make a measurable difference in corrosion control.

At Hull 2 Prop, we focus on providing optimal marine care through professional underwater maintenance and repairs across Florida. Our experienced dive teams deliver consistent service for residential and commercial clients, including hull cleaning and propeller repair, ensuring your vessel stays protected year-round.

Contact us today to schedule a professional zinc anode inspection and replacement before corrosion becomes costly.