A proper sacrificial anode calculation is essential for protecting your boat from corrosion and extending the life of critical underwater components. This article explains how anode sizing works, what factors influence calculations, how hull type affects protection needs, and why correct planning is key to long-term vessel performance.

Why Sacrificial Anode Calculation Matters

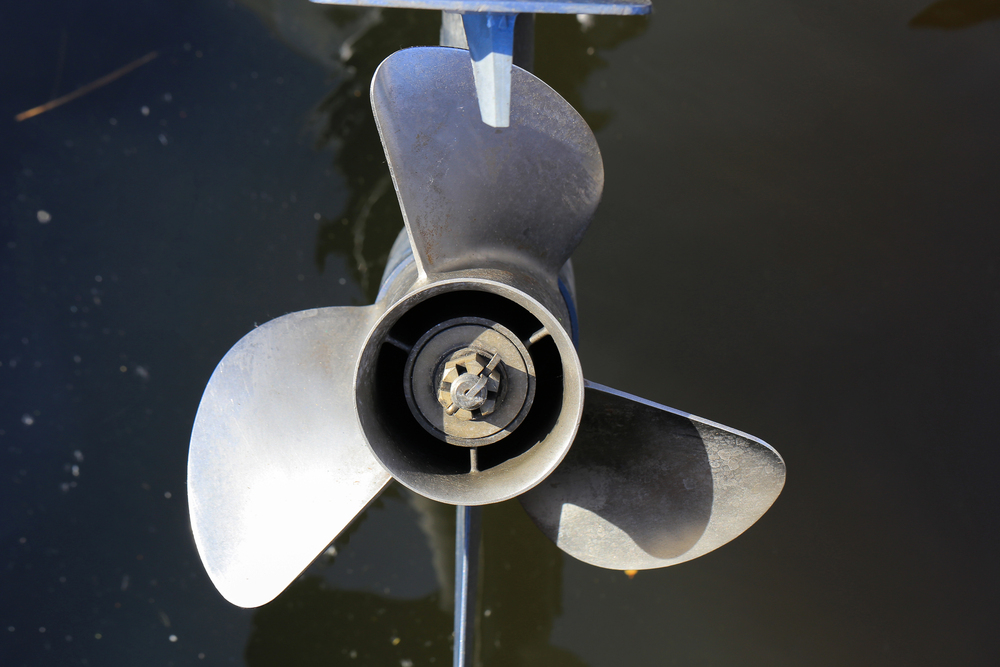

Sacrificial anodes protect metal components by corroding first, preventing damage to the hull, propeller, shafts, and other submerged parts. When an anode is undersized, it wears out too quickly and leaves the vessel exposed.

When oversized, it may not activate properly or can create uneven protection. A reliable sacrificial anode calculation ensures the anode provides consistent corrosion defense over its intended service life without unnecessary replacements.

Key Factors Used in Anode Sizing

Several variables are considered when determining the right anode size. The total surface area of exposed metal is the primary factor, as larger metal areas require more protective current. Water type also plays a major role, since saltwater, brackish water, and freshwater have different conductivity levels.

Vessel usage matters as well, because boats that operate frequently or remain docked near other vessels may experience higher electrical activity and faster anode consumption.

Understanding Sacrificial Anode Design Calculations

Accurate sacrificial anode design calculations go beyond simple size estimates. These calculations consider current demand, expected anode efficiency, and desired service duration.

Engineers evaluate how much electrical current is required to protect the submerged metals and match it with an anode material capable of delivering that current over time. This process ensures the anode depletes evenly and maintains effective contact throughout its lifespan.

Hull Type and Metal Exposure

The hull’s construction directly affects anode requirements. Aluminum hulls demand careful planning because incorrect anode material selection can accelerate corrosion instead of preventing it. Steel hulls often require larger or multiple anodes due to higher current demand.

On a sacrificial anode ship hull, the layout and distribution of anodes are just as important as total size, ensuring uniform protection across all submerged areas.

Placement and Distribution of Anodes

Even with accurate calculations, poor placement can reduce effectiveness. Anodes should be installed close to the components they protect and positioned to allow unrestricted water flow.

Distributing multiple smaller anodes rather than relying on a single large one often provides more balanced protection. This approach also allows easier monitoring and replacement of worn boat sacrificial anodes during routine inspections.

Common Calculation Mistakes to Avoid

One common error is ignoring changes in vessel usage or environment. Moving a boat from freshwater to saltwater without recalculating anode needs can lead to rapid depletion.

Another mistake is overlooking added equipment, such as new propellers or underwater fittings, which increases the exposed metal area. Regular reassessment of sacrificial anode calculation requirements helps prevent these costly oversights.

When Professional Assessment Is the Better Choice

While basic guidelines are helpful, real-world conditions can vary significantly. Electrical interference from nearby boats, marina wiring issues, and onboard systems can all impact anode performance. Professional divers and marine technicians can evaluate wear patterns, confirm proper sizing, and adjust anode placement to ensure optimal protection based on actual operating conditions.

Achieve Reliable Corrosion Protection with Accurate Anode Calculations

Correct anode sizing and placement protect your vessel from unnecessary corrosion and reduce long-term maintenance costs. Thoughtful planning ensures your anodes perform as intended throughout their service life.

At Hull 2 Prop, we focus on delivering optimal marine care through professional underwater maintenance and repairs across Florida. We work with dedicated dive teams to provide consistent service, including hull cleaning, anode replacement, and propeller repair, for both residential and commercial vessels.

Contact us today to schedule a professional anode assessment and keep your vessel protected year-round.