How long does a sacrificial anode last? Understanding this is critical for maintaining a ship’s structural integrity and avoiding premature corrosion damage.

This article explains the typical lifespan of sacrificial anodes, the key factors that affect their wear rate, how different sacrificial anode materials perform in various water conditions, and when replacement is necessary to ensure consistent protection for any sacrificial anode ship.

What Is a Sacrificial Anode and Why Does It Matter?

A sacrificial anode is a block of metal intentionally designed to corrode instead of the more important metal parts of a vessel. It works through a process called cathodic

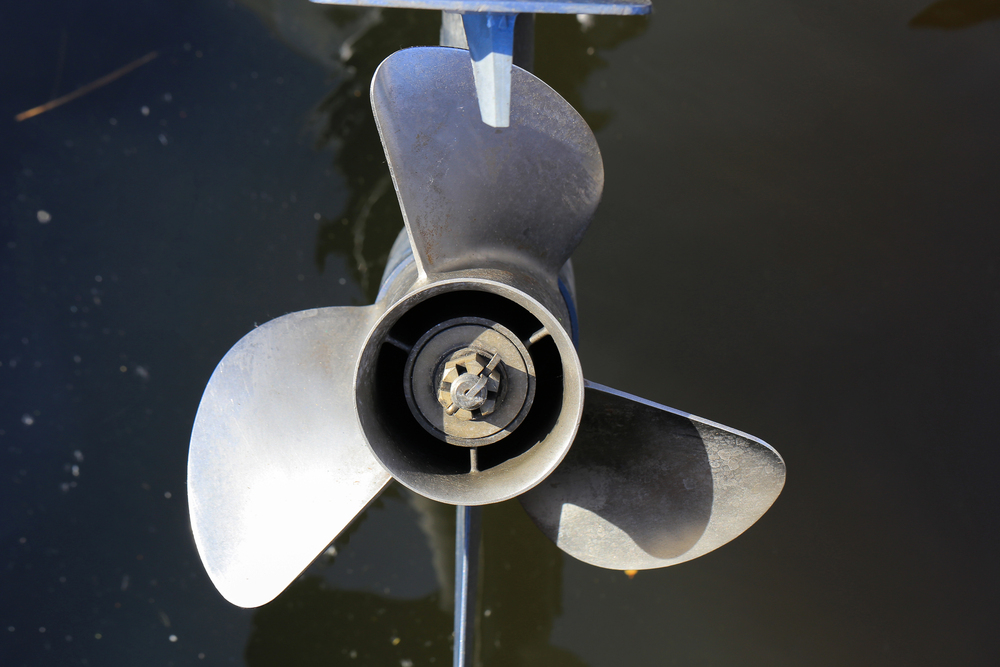

protection, where the anode sacrifices itself to protect the hull, propeller, shaft, and other submerged components. On a sacrificial anode ship, this protection is not optional but a fundamental part of routine marine maintenance. Without properly functioning anodes, corrosion can spread quickly and lead to structural damage, performance issues, and expensive repairs.

Average Lifespan of a Ship Sacrificial Anode

The lifespan of a sacrificial anode typically ranges from six months to three years. How long it lasts depends on several variables, including water conditions, vessel activity, and the type of anode installed.

In many cases, anodes are designed to wear down gradually and should be replaced once about 50 percent of the material has been consumed. Vessel operators who understand how long a sacrificial anode lasts can schedule inspections and replacements before corrosion risks increase.

Factors that Affect Anode Longevity

Several key factors influence how long an anode will remain effective:

- Water Type: Saltwater is more aggressive than brackish or freshwater, causing anodes to degrade faster.

- Electrical Activity: Stray electrical currents from onboard systems or nearby vessels can accelerate anode consumption.

- Vessel Usage: Ships that operate continuously or remain docked near other vessels may experience faster anode wear.

- Installation Quality: Poor contact between the anode and the metal surface reduces effectiveness and shortens lifespan.

Regular underwater inspections help identify these issues early and extend the protection anodes provide.

The Role of Sacrificial Anode Material

Choosing the right sacrificial anode material is just as important as monitoring its condition. Zinc, aluminum, and magnesium are the most commonly used materials, each suited to different water environments.

Zinc is widely used in saltwater, aluminum performs well in both salt and brackish water, and magnesium is best for freshwater applications. Selecting the wrong material can cause the anode to deteriorate too quickly or fail to provide adequate protection.

Signs that an Anode Needs Replacement

Visible wear is the clearest indicator that an anode should be replaced. If the anode appears heavily pitted, unevenly eroded, or reduced to half its original size, it is no longer offering full protection. Inconsistent wear patterns may also signal electrical issues onboard.

Replacing worn boat sacrificial anodes before complete depletion ensures continuous corrosion protection and reduces the risk of damage to underwater components.

Maintenance and Inspection Best Practices

Routine inspection is essential for extending anode life and maintaining vessel safety. Most marine professionals recommend checking anodes during scheduled hull cleanings or at least once every six months. Combining inspections with hull maintenance allows divers to assess wear, confirm proper installation, and replace anodes as needed.

Why Anode Replacement Should Never Be Delayed

Delaying anode replacement exposes critical components to direct corrosion. Propellers, shafts, and thru-hull fittings are expensive to repair and replace compared to the relatively low cost of new anodes. On a working sacrificial anode ship, timely replacement supports vessel performance, fuel efficiency, and long-term structural integrity.

Protecting Your Vessel Through Timely Anode Replacement

Sacrificial anodes are a simple but powerful defense against corrosion, and understanding their lifespan helps prevent avoidable damage. When monitored and replaced on schedule, they protect your vessel’s most valuable underwater components.

At Hull 2 Prop, we focus on delivering dependable marine care you can trust. We specialize in underwater maintenance and repairs throughout Florida, offering consistent service through dedicated dive teams who understand your vessel’s needs. Our services include hull cleaning, anode replacement, and propeller repair, all designed to keep your vessel operating at its best.

Schedule a professional anode inspection today and let Hull 2 Prop help safeguard your vessel from corrosion year-round.