Why is zinc used as a sacrificial anode? Knowing why is key to protecting boats from corrosion and avoiding costly underwater damage. This article explains how zinc works, why it is effective in marine environments, where it is best used, and how proper maintenance keeps vessels protected over time.

How Sacrificial Anodes Protect Boats

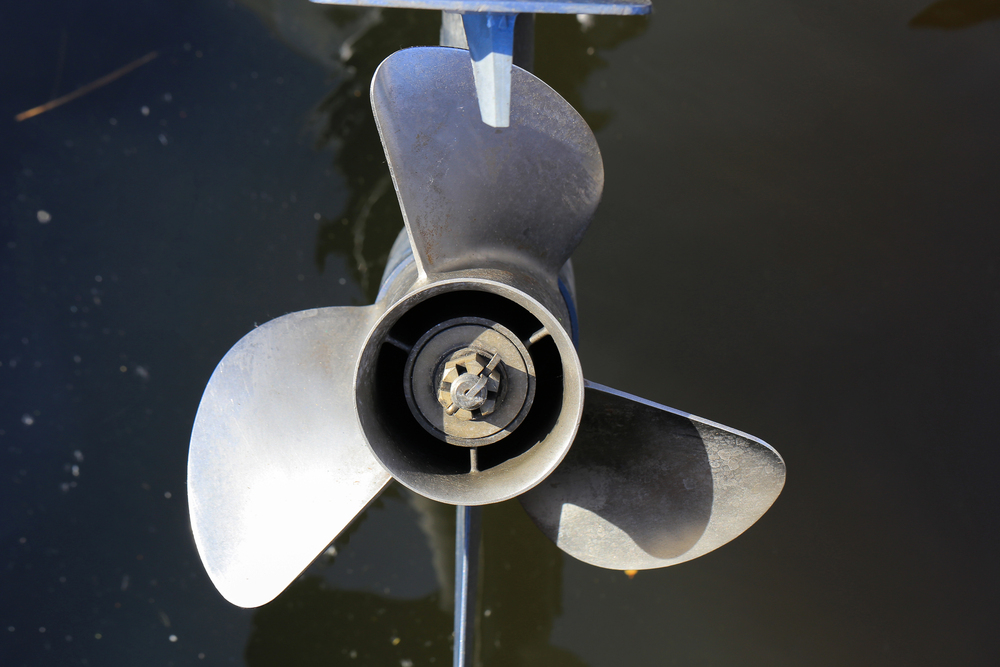

Sacrificial anodes protect underwater metal components by corroding in place of more valuable parts such as propellers, shafts, and hull fittings. This process, known as cathodic protection, ensures that electrical corrosion targets the anode instead of structural metals. On boats and larger vessels alike, this protection is essential for maintaining safety, performance, and long-term durability.

Why Zinc Performs Well in Marine Environments

One of the main reasons why zinc is used as a sacrificial anode is its electrochemical properties. Zinc is more electrically active than steel, bronze, and stainless steel, which allows it to corrode first when submerged. In saltwater environments, zinc provides stable and predictable performance, making it a reliable option for corrosion protection.

Zinc also reacts at a controlled rate, which means it wears down gradually rather than failing suddenly. This steady consumption allows vessel owners to monitor anode condition and plan replacements before critical components are exposed.

Zinc Compared to Other Anode Materials

While aluminum and magnesium anodes are also used, zinc remains a preferred option in many saltwater applications. Magnesium is too active for saltwater and can deplete rapidly, while aluminum, although versatile, may not always be ideal for certain hull types or operating conditions.

On a sacrificial anode on ships, zinc continues to be widely used for hulls, rudders, and shafts operating in consistent saltwater conditions.

Where Zinc Anodes Are Commonly Installed

Zinc anodes are typically installed in areas with constant water exposure and high corrosion risk. These include propeller shafts, trim tabs, thru-hull fittings, and rudders. Proper placement ensures that electrical currents are drawn away from critical components and toward the anode.

Using correctly sized and well-positioned boat sacrificial anodes improves protection efficiency and reduces uneven wear. Regular inspections help confirm that zinc anodes remain securely attached and electrically bonded.

Environmental and Operational Considerations

Zinc anodes perform best in saltwater environments with moderate conductivity. In brackish or freshwater, zinc may develop an oxide layer that reduces effectiveness. Vessel operators should always consider operating conditions before selecting an anode material.

As vessels age or usage changes, reassessing corrosion protection is critical. Even the best sacrificial anode company recommendations rely on routine inspection and proper replacement intervals to maintain effectiveness.

Maintenance and Replacement Best Practices

Zinc anodes should be inspected at least every six months or during scheduled hull cleanings. When an anode has lost roughly half of its original mass, replacement is recommended. Ignoring worn anodes increases the risk of corrosion spreading to expensive underwater components.

Consistent maintenance ensures zinc continues to function as intended and protects both small recreational boats and commercial vessels.

Protecting Your Boat with Proven Zinc Anode Solutions

Zinc sacrificial anodes offer reliable, predictable corrosion protection in saltwater environments when properly sized and maintained. Their steady performance makes them a long-standing solution for marine vessels.

At Hull 2 Prop, we focus on providing optimal marine care through professional underwater maintenance and repairs across Florida. We support our clients with experienced dive teams offering hull cleaning, boat sacrificial anode replacements, and propeller repair to keep vessels protected and operating efficiently.

Schedule an inspection today and protect your boat from corrosion before damage begins.