How does sacrificial anode prevent corrosion? Understanding its function can help you extend the life of your vessel. Boats operate in harsh marine environments where metal components are constantly exposed to saltwater, oxygen, and other corrosive elements.

Without proper protection, corrosion can weaken the hull, propellers, and other underwater fittings. Sacrificial anodes play a critical role in preventing this damage through a process known as cathodic protection. By sacrificing themselves, these anodes preserve the boat’s essential metal structures and reduce costly repairs.

The Principle of Sacrificial Anodes

Sacrificial anodes protect metal surfaces using a simple electrochemical process. When two dissimilar metals are connected in an electrolyte such as seawater, a natural electrical current flows between them. The more active metal, known as the anode, corrodes first, while the less active metal, or cathode, is preserved.

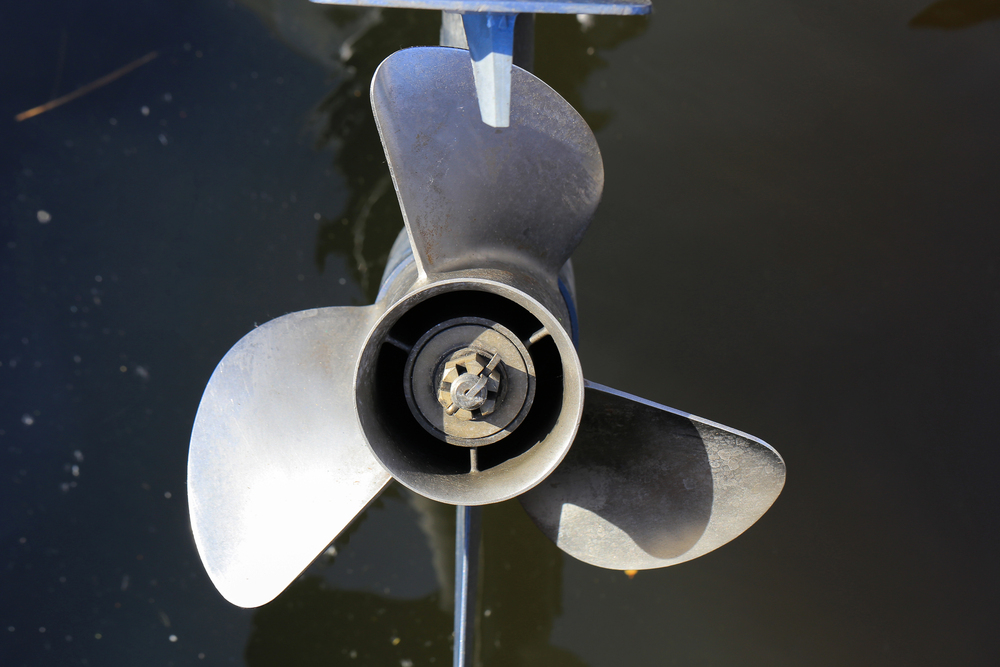

In a boat, the hull or propeller becomes the cathode, and the attached anode, usually made of zinc, aluminum, or magnesium, corrodes in its place.

This system is known as sacrificial anode corrosion protection. It ensures that corrosion targets only the anode rather than the structural parts of the vessel. Visualizing a sacrificial anode cathodic protection diagram can help boat owners understand how electrons move from the anode to the hull, neutralizing corrosive reactions that would otherwise damage vital components.

Types of Sacrificial Anodes and When to Use Them

Not all anodes perform equally in different water conditions. Choosing the correct material ensures long-lasting protection.

- Zinc anodes are the traditional choice for saltwater use. They are durable, affordable, and widely available, making them ideal for boats that stay in marine environments year-round.

- Aluminum anodes have gained popularity for both salt and brackish water. They offer better efficiency and last longer than zinc while being lighter in weight.

- Magnesium anodes are highly active and best suited for freshwater. However, they corrode too quickly in saltwater and can cause overprotection.

Selecting the correct type of anode based on the water where the boat operates ensures optimal performance. The wrong choice may lead to premature consumption or insufficient protection.

Installation and Placement Strategies

Proper installation is vital to the effectiveness of sacrificial anodes. They must be electrically connected to the metal parts they are meant to protect, forming a complete circuit. Common installation points include the hull, rudder, trim tabs, propeller shafts, and outdrives.

Each anode should have full contact with bare metal and be securely fastened. Even a small layer of paint or sealant can disrupt the electrical connection. Additionally, placement should be distributed evenly so that every metal surface below the waterline is covered.

A sacrificial anode cathodic protection diagram often illustrates the recommended positioning for various boat designs. Following these guidelines helps ensure balanced corrosion protection across all underwater components.

Maintenance, Monitoring, and Replacement

Like any consumable part, sacrificial anodes require routine inspection and timely replacement. Over time, they deteriorate as they fulfill their purpose. Regular maintenance helps prevent gaps in protection that could allow corrosion to occur.

Inspect anodes every few months, or more frequently if the boat spends extended time in the water. Signs of pitting, cracking, or uneven wear may indicate it’s time for replacement. When more than 50–70 percent of the anode has corroded, it should be changed immediately.

For boats that remain docked for long periods, scheduling professional divers to perform underwater boat repairs and inspections ensures the anodes are functioning correctly. Keeping detailed records of replacement dates also helps predict service intervals more accurately.

Benefits and Limitations

The main advantage of sacrificial anodes is that they provide continuous, passive protection without needing an external power source. They are reliable, inexpensive, and highly effective in preventing corrosion on hulls, shafts, and fittings.

However, they have limitations. Anodes have a finite lifespan and must be replaced periodically. If improperly installed or if the wrong material is used, the system’s effectiveness can be reduced. Additionally, non-metallic or composite hulls do not directly benefit from this form of protection and may require alternative methods.

Long-Term Protection Through Proper Anode Care

Sacrificial anodes are your boat’s first line of defense against corrosion, silently working to protect critical components and extend vessel lifespan. Consistent inspection and proper replacement practices can prevent costly damage and ensure reliable protection for years to come.

At Hull2Prop, we’re dedicated to providing exceptional marine care through professional underwater boat repairs and expert maintenance of boat sacrificial anodes. We specialize in underwater maintenance and repair services across Florida, offering personalized solutions built on quality, reliability, and precision.

With our 24/7 service availability, expert help from Hull2Prop is always just a call away. Get in touch with us now.